BI.MAG Bar storage

The real innovation that comes from experience

BI.MAG Automatic Warehouses

BI.MAG Automatic Warehouses

The containers can have different construction forms: reticular containers for the storage of profiles and long material in general, sheet metal containers for the material to be protected, or closed-bottom boxes for containing glimpses, spare parts or boxes of accessories. The drawers are sized and inserted into the machine by our technical office according to the requests of the end customer. BI.MAG automatic warehouses allow with customized solutions the storage of long material such as tubes, profiles and bars but also automatic warehouse solutions for pallets, molds, semi-finished products, heavy accessories, hydraulic and mechanical components.

Ciampalini also manufactures external warehouses making greater use of the height up to heights of over 20 meters. An external warehouse also allows you to better optimize the spaces and limit the overall dimensions of the materials inside the workplace. Our company is able to provide a self-supporting structure with turnkey insulated panels

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

The solution for long material storage

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

The solution for long material storage

Automatic Warehouses BI.MAG with drawers are the ideal system for the vertical storage of steel bars and enclosures with lengths of 3 m, 6 m. and 12 m., heavy accessories, semi-finished products, components, molds and long material in general. The load capacity per loading unit ranges from a minimum of 5000 kg. to a maximum of 6000 kg. BI.MAG warehouses are a practical and economic solution, suitable for both production and commercial distribution. They are often installed next to a cutting machine in order to send the material directly into the working position. BI.MAG warehouses can be customized to meet any specific need for the storage and handling of bars and long material.

Contacts

TECHNICAL FEATURES OF OUR BI.MAG

Structure

The structure of the BI.MAG Automatic Warehouses is in steel, suitably sized. The drawers are arranged on two, four or more 'towers' with relative shuttle that picks up the selected drawer until it is transported to the loading / unloading bay. The BI.MAG warehouse. it can have one or more loading / unloading bays, with front or side exit with respect to the machine arrangement.

Dimensions of the drawers (UDC)

The drawers are sized and inserted into the machine by our technical office according to the requests of the end customer.

• Maximum drawer length: 15 m

• Load rate per drawer (UDC)

• Capacity min. per drawer: 500 Kg

• Max. per drawer: 3000/5000 Kg

• Standard drawer for aluminum profiles: 750/1000 Kg • Standard drawer for ferrous materials: 3000 Kg

Some accessories supplied with the BI.MAG warehouses

- Runways with hoists with linear and transversal motion for the movement and loading / unloading of the bundles of profiles to be applied to the warehouse itself.

- Elevators with adjustable button-controlled arms to be applied under the container in the exit position. The lift raises the material and brings it above the level of the container for feeding the cutting centers or for loading from a forklift or overhead crane.

- Front or side roller conveyors to the warehouse for handling the profiles in bundles or single bars.

- Loading cells with display to perform instant weighing of the material in each individual container

- "Retractable" motorized trolleys for the drawer exit both laterally and frontally.

- Hydraulic lift to facilitate the loading and unloading of heavy bundles by means of a forklift truck.

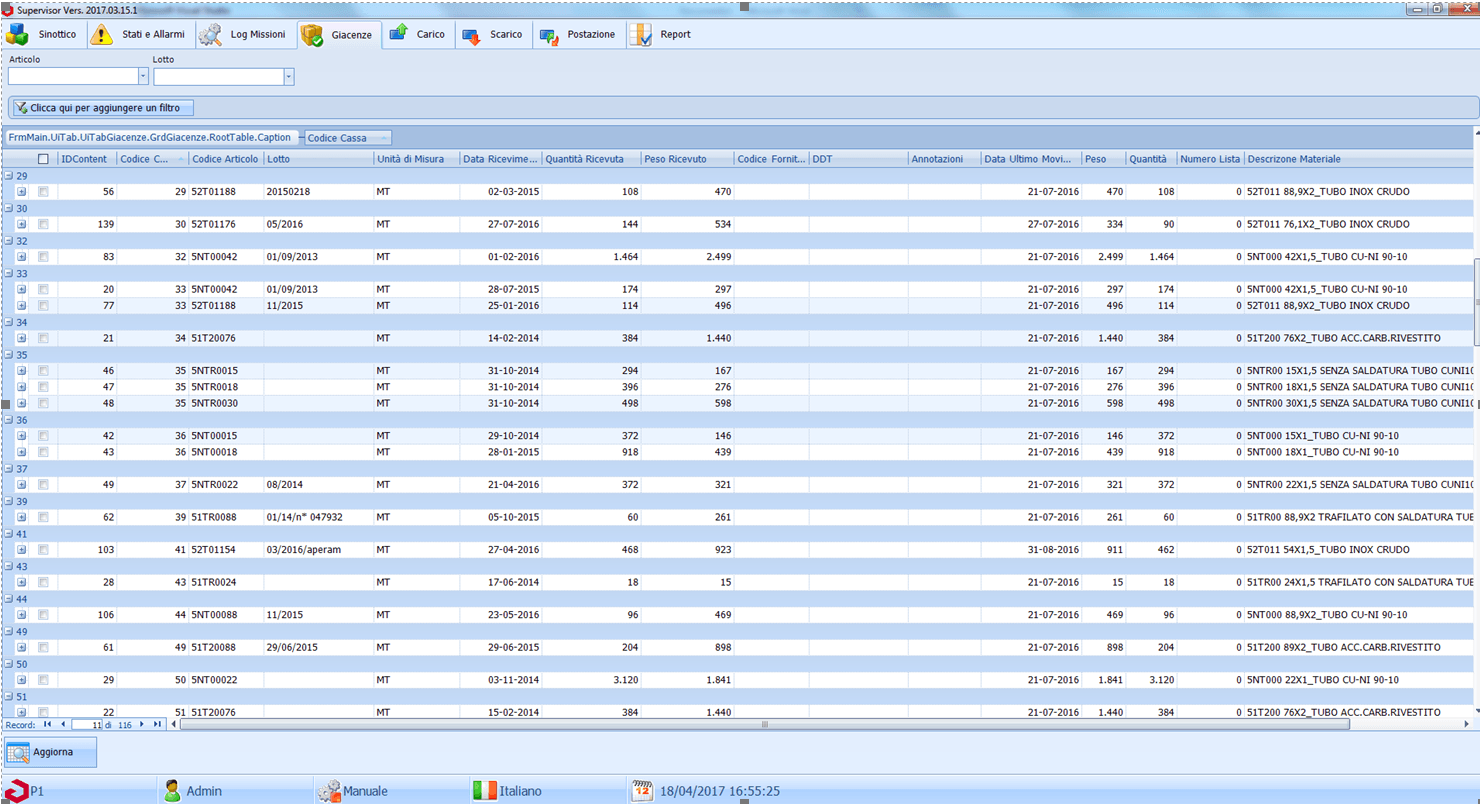

Warehouse management software

The standard command of BI.MAG. it consists of a numeric keypad on which the operator selects the number of the container required and this arrives in the unloaded loading position. The useful time to exchange the container is on average 80 seconds. The parameters that act on the warehouse PLC are also adjusted from the keyboard.

- Read more

The WMS software developed by CIAMPALINI is a monitoring system for the supervision and networking of one or more BI.MAG systems. It will be possible to manage the BI.MAG automatic warehouse. through the PC, from which you can search for the items in the containers, view and print the quantities of material contained in each individual container or in the warehouse. You can therefore have a quick inventory always updated and displayed in real time.

Slide title

Write your caption hereButton

Get in touch with us

HEADQUARTERS

Via Giuseppe Di Vittorio,34, Empoli, 50053 50053, Italy

PHONE

+39 0571 81066

E-MAIL

info@ciampalini.it

WORKING HOURS

- Mon - Fri

- - -

- Sat - Sun

- Closed

HEADQUARTERS

Via Giuseppe Di Vittorio, 34 50053 Empoli (FI)

PHONE NUMBERS

+39 0571 81066

info@ciampalini.it

WORKING HOURS

- Mon - Fri

- - -

- Sat - Sun

- Closed

Vat Reg.No 04866800487 | Legal information

| Privacy and Cookie Policy